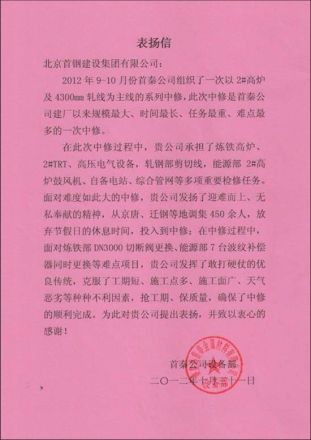

From September 26 to October 10, 2012, after a period of 15 days, Shougang Construction Group successfully completed a series of medium repairs for Shouqin Company in 2012, mainly focusing on the 2 # blast furnace and 4300mm rolling line.

This is the largest, longest, heaviest, and most difficult overhaul of Shouqin Company since its establishment in 2004. It involves multiple regions, high technical content, complex processes, and requires a large amount of manpower and material equipment. The participating units of Shougang Construction Group have worked together to successfully complete multiple important maintenance tasks such as ironmaking blast furnace, 2 # TRT, high-voltage electrical equipment, steel rolling department cutting line, energy department 2 # blast furnace blower, self owned power station, and comprehensive pipeline network with high quality and quantity. It has been praised by the owner.

Replacement of glasses valve group for gas pipeline with a diameter of 2.4 meters in blast furnace

Replacing the corrugated compensator in the gas pipeline with a blast furnace diameter of 2.4 meters

Reinstall the airtight box on the top of blast furnace No.2

Reinstallation of blast furnace gas ignition device